WEST VIRGINIA

Solutions for Radioactive Slurry Waste

OVERVIEW:

In May of 2019, the customer Secur O&G,LLC an Oil and Gas waste processing facility located in West Virginia was in need of a processing system to treat and process multiple contaminated waste streams. The Secur O&G facility is the largest of its type in the region and has the current capability of processing 10,800 barrels of slurry waste per day. The contaminated waste streams include, but are not limited to the following: oil based drill cuttings, water based drill cuttings, frac water, produced water, slurry liquids with high radiocative material including NORM and TNORM, cement water, waste water with high and low PH levels , frac gels, tank bottom and pit clean out slurry with various chemical waste and other various waste streams. The customer was also in need of a system to increase productivity of the facility and reduce the overall cost of consumable products utilized for tradition solidification and disposal methods.

Challenge:

Separate solids from liquids to increase productivity of the facility. Reduce the overall solidification consumable processing cost of traditional methods by 50%.

Solution:

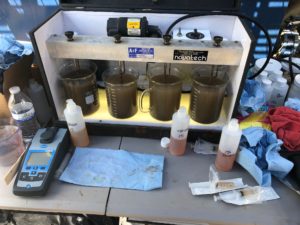

Green Earth Technologies International, Inc. proposed using the patented Green Earth Machine® GM-300 slurry waste treatment system as the primary system to separate solids and liquids from the slurry waste stream.

Results:

Utilizing the Green Earth Machine® GM-300 slurry waste treatment system allowed the operator to successfully reduce the overall solidification costs from approximately $200,000 per month to less than $35,000 per month which outperformed and exceeded the original goal of 50% consumable cost reduction.

Over 130,000 barrels of contaminated waste slurry have been separated into solids and liquids utilizing the Green Earth Machine® GM-300 slurry waste treatment system. Over 10,000 Tons of solids have been processed which has increased the productivity of the facility.

Green Earth Processing Systems™